No.1 Manufacturing Company of Industrial Blenders, Ribbon Blenders in India | Blender Mixing Machines for Powder & Granules

In the current competitive industrial environment, effective and consistent mixing equipment is an important consideration in the quality and consistency of products. An Industrial Blender is a machine that is applicable in various industries, including food, pharmaceuticals, chemicals, plastics, and agriculture. These machines are intended to be used with large amounts of powders, granules, and raw materials, which require even blending to be used in production.

Being a major Industrial Blender Manufacturer, we have specialized in providing high-quality and durable blending machines to suit the unique requirements of various industries. It could be the mixing of dry powders, granules, or semi-wet materials, but our industrial blenders are able to make it as efficient and similar as possible.

What is an Industrial Blender Machine?

An Industrial Blender is a large-scale mixing device that has been designed with the purpose of mixing bulk materials in a uniform combination. These machines are heavy-duty machines, unlike small kitchen blenders, which are used in manufacturing plants. They make sure that all the particles of the material are mixed evenly, which is critical in terms of product quality in industries such as pharmaceuticals and food processing.

Industrial blenders have a capacity of hundreds and possibly even thousands of kilograms per batch, which makes them indispensable to mass production. They are designed differently, based on application, and the main objective is the same: continuous and dependable mixing.

Various Types of Industrial Blenders

Dissimilar industries need different mixing solutions, which is why a variety of Industrial Blenders are offered:

1. Ribbon Blender

The Ribbon Blender, which is one of the most popular, is a horizontal U-shaped trough containing helical-type ribbons that rotate the material in opposite directions. It is a very effective mixture of dry powders, spices, cosmetic powders, and chemicals.

2. Double Cone Blender

This Double Cone Blender has a vessel designed in the shape of a cone, which spins around its axis. It is specifically designed to blend free-flowing solids and powders in the pharmaceutical and chemical sectors.

3. V-Blender

The V-Blender is also known as a twin-shell blender, a type of blender that is made up of two inclined cylinders, joined together in a V shape. The design is unique so that it blends easily without overworking fragile materials. It has wide application in the food industry and pharmaceuticals.

4. Octagonal Blender

An octagonal blender is octagonal-shaped with a drum that is used in blending large quantities of dry material. It operates at low speed, so it provides good mixing, and degradation of the material is low; thus, it can be used in sensitive products.

5. Paddle Blender

A Paddle Blender is a mixer that incorporates paddles on a rotating shaft. It can be used in the blending of both powders and semi-wet components, which are usually utilized in the food and agricultural sectors.

Key Application of Industrial Mixer Blender

Industrial Blenders are so versatile that they cannot be ignored in various industries. It may be used in some typical forms of application, such as:

- Food & Beverage Industry: blending flour, spices, baking materials, protein powders, instant mixes and beverages.

- Pharmaceutical Industry: The process of combining active pharmaceutical ingredients (APIs) and excipients to achieve uniform dosage during tablet and capsule formulations.

- Chemical Industry: Grinding chemical powders, fertilizers, coloring, and plastic granules.

- Cosmetics Industry: Blending powders, creams, and cosmetic bases.

- Agriculture Industry: It is the mixture of animal feed, seeds, and fertilizers.

The applications should be precise, and the selection of an appropriate Industrial Blender Manufacturer is important to maintain the same quality of products.

The Benefits of an Industrial Mixing Equipment

- Consistent Batching Quality of Mixed Products - Assures the same product batches.

- High Capacity - Processes large volume production.

- Versatility - Appropriate for a large selection of materials.

- Energy efficient - Built to operate at a low cost.

- Cleaning and Maintenance Easy – Pharma and food industry hygienic design.

- Long-Lasting and Strong-Duty – Constructed with tough materials to perform all the time.

How To Select the Right Industrial Blenders Manufacturers?

The selection of the right Industrial Blender Manufacturer can make a significant difference in the efficiency of production. Take into consideration the following factors:

Blender Type/Capacity

Choose a design that suits your use (powder, granules, semi-wet).

Quality Standards

Make sure that the manufacturer is adhering to GMO, ISO, and international safety certifications.

Material of Construction

Stainless steel will be used for hygienic considerations in the food and pharma industry.

After-Sales Service

Spare parts, maintenance, and technical support are needed to ensure long-lasting reliability.

Customization

The manufacturers are supposed to provide custom designs to suit particular needs.

Why Should You Select Arvinda Blenders for High Capacity Industrial Blender Manufacturer?

Being a reliable Industrial Blender Manufacturer, we combine years of experience, innovation, and quality-orientedness. This is the reason why industries want us:

- 10+ years of mixing equipment design experience.

- Advanced Technology of fine blending.

- Industry Specific Solutions.

- Premium-grade Construction and materials.

- Global Supply Network that guarantees timely supply.

- Long-term performance after-sales services.

| Brand | Arvinda blenders |

| Production Capacity | 50 Kg/h |

| Material | Mild Steel |

| Dimension | 1780x1400x2000 mm |

| Motor | 2 HP |

| No Of Phase | Single Phase |

| Voltage | 620 V |

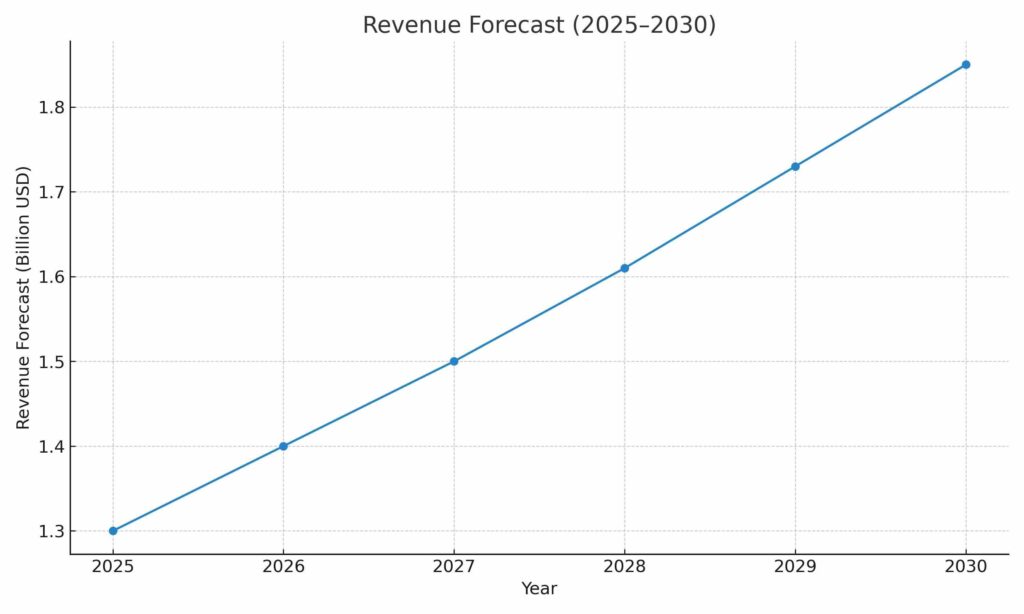

Market Growth of Industrial Blender Manufacturer ( 2025-30 )

The industrial blender market will reach a high growth between 2025 and 2030 with a projected CAGR of 6-8. Market forecasts show that it is bound to exceed USD 3.2B by 2030, as compared to USD billion in 2024. The major drivers of growth are the growing demand in the pharmaceutical and nutraceutical industries, the growing focus on food safety requirements, the growing application in the bulk materials handling industry, and the substantial technological innovation leading to greater efficiency and automation in blending solutions.

Key Market Driver

- Growth in the pharmaceutical industry.

- Increased demand for GMP-compliant blenders.

- Produced more generics and nutraceuticals.

- Food/Beverage Industry Growth.

- Increase in the intake of processed foods, protein powders and spices.

- Demand of hygienic and stainless-steel mixing equipment.

Which Kinds of Materials are mixed in Industrial Blenders?

Industrial blenders are multi-purpose machines that are meant to work with the largest possible number of materials in various industries. They provide consistency, uniform mixing, and quality of the end product. Industrial blenders are mixed with some of the following:

1. Powders

- Powders (food, spices, protein powders).

- Drugs (API, excipients)

- Detergent, pigment, fertilizer, etc.

2. Granules

- Plastic granules (PVC, PE, PP)

- Tablet and capsule pharmaceutical granules.

- Construction material: mineral granules.

3. Liquids & Semi-Liquids

- Food industry syrups, oils and food sauces.

- Chemicals and emulsions.

- Cosmetic gels, lotion, and creams.

4. Solids with Liquids

- Putting a coating on powders with binding liquids.

- Wetting granulometry of dry powders.

- Slurries are mixed in mining industries and chemical industries.

5. Specialty Materials

- Paint and plastics, colorants and pigments.

- Adhesives and resins

- Nutraceutical and herbal combinations.

An industrial Blender is one of the important pieces of equipment in an industry that depends on precise and dependable mixing. The machines are used in food processing, pharmaceuticals, and chemicals to guarantee uniformity, efficiency, and productivity in the manufacturing processes.

We are an efficient Industrial Blender Manufacturer offering high-performance blenders that satisfy the global standards and industry-specific requirements. You may reach out to us to discuss your needs in case of durable, efficient, and cost-effective blending solutions.

👍 Contact us today to locate the ideal Industrial Blender to use in your company.

FAQs

A ribbon blender is used to mix thoroughly with dual helical ribbons, which are suitable for powder. A paddle mixer is used when the material is delicate and requires a soft mixer.

Yes, there are industrial blenders which have liquid injection capability so as to mix the powders and liquids with ease.

Capacity is based on your batch size of production, the type of material, as well as the time you want to mix it. Ask the manufacturer to prepare an individual solution.

Yes, the majority of blenders are cleaned up easily and require minimal downtime. The construction is made of stainless steel, assuring hygiene.

Industrial blenders are used in pharmaceuticals, food processing, chemicals, cosmetics, polymers, animal feed, and specialty industries.