We are One Of The Leading Manufacturing Company For Ribbon Blenders & Ribbon Mixer in India

“Arvinda blenders” offers a wide assortment of Ribbon Blenders that are created by specialists utilizing cutting-edge technology and are widely accepted by valued customers. We have reached Ahmedabad and most of India in a short period of time by providing them with the most appropriate products. We also give customised solutions based on the needs of the client.

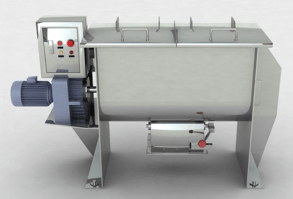

Ribbon Blender is a wide range of industrial mixers that we manufacture. There are several models available, ranging from lab to heavy-duty. These are the best dry powder mixing products with the best results and the lowest cost. With a working capacity of 5 to 10,000 litres, this mixer is constructed in a U shape.

Ribbon blenders are one of the most flexible and commonly used industrial mixing machines. They are designed to combine powders, granules, and other bulk materials and provide a homogenous blend and saving time and energy.

As one of the top ribbon blender manufacturers, we have specialized in manufacturing quality, durable, and efficient blenders that can be used in various industries such as food processing, pharmaceuticals, chemicals, and plastics.

What is a Ribbon Blender?

A ribbon blender is a type of industrial mixing machine that relies on a combination of inner and outer helical ribbons in order to mix materials against each other. This type of design provides a complete and uniform mixture of powders, granules, and other dry or semi-dry products.

The main Features of Ribbon Blenders

Homogenous Blending: Ribbons with a dual helix are used to give uniform mixing.

High Capacity: It is applicable to large and small batch production.

Durable Construction: This is constructed using stainless steel or any other material that is resistant to corrosion.

Customizable: This is customizable to meet industry specifications.

Easy Maintenance: The model is engineered to be easy to clean and to have low downtimes.

Application

- Food Industry: Blending food with flour, spices, sugar, salt, etc.

- Pharmaceutical Industry: A combination of powders, granules, and active ingredients to make tablets or capsules.

- Chemical Industry: Unification of fertilizers, detergents and chemical powders.

- Plastic and Polymer: Raw materials are mixed in a uniform way to ensure a uniform quality of the products.

Benefits

- Efficient Mixing: saves time as well as provides uniformity.

- Scalable: It comes with various capacities on various production volumes.

- Energy Saving: It uses less energy than other blenders in the industry.

- Strong and Long Lasting: Designed to withstand industrial use.

- Custom Designs: Can be designed to be used in heating, cooling, or liquid injection.

Why Choose Us as the Best Ribbon Blender Manufacturer?

We offer, as a reliable ribbon blender manufacturer:

- Personalized Solutions: Designed to meet your production requirements, material types.

- Durability: Stainless steel and corrosion-resistant materials to ensure long life service.

- Advanced Technology: New design to achieve efficient, uniform and fast mixing.

- After-sales services: Special services, maintenance services and availability of parts.

- Competitive Pricing: Quality industrial blenders at competitive prices.

Types of Ribbon Blenders

General-purpose Ribbon Blenders

To mix general powder and granules.

Ribbon Blenders

They are heated and cooled and fitted with jackets on temperature-sensitive materials.

Liquid addition

Can mix powders with liquids to produce uniform pastes or slurries.

Custom Ribbon Blenders

This is created to meet industrial needs.

Ribbon Blender Maintenance Tips

- Clean after each batch to avoid contamination.

- Gear and moving bodies often lubricate.

- Check ribbons and change the ones needed.

- Check motor centering and adjustment to proper running.

- Check that safety interlocks and emergency stops are operating.