Manufacturer of Ribbon Mixer - High-performance industrial mixing solution

“ARVINDA BLENDERS” is India’s biggest Unique Manufacturing Company, Supplier, and Exporter of high-quality, energy-efficient industrial mixing equipment such as Ribbon Blender, Ribbon Mixer, Tray Dryer, and Conical Screw Mixer that are Manufacturer in India. Due to the design and shape of the mixing ribbon and product container, the ribbon blender produces the best results for blending dry powder and granules. We make Ribbon blenders for pharmaceutical, food, chemical, and cosmetic products, etc. Our name as “ARVINDA BLENDERS” comes at the top spot, whenever there is a rank given from one to ten to Ribbon Blender Manufacturers In Ahmedabad.

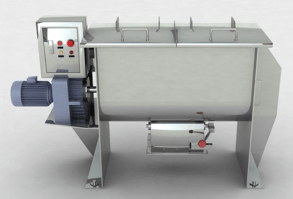

Ribbon Mixer is a very effective industrial mixing equipment that is utilized in blending uniformly dry powders, granules, and bulk solid materials. Being a reputable Ribbon Mixer Manufacturer, we are capable of designing and producing high-tech ribbon mixers which provide high uniformity in mixing with minimum processing time. The machine is designed with a horizontal U-shaped trough with internal and outer helical ribbons, which revolve in opposite directions, providing a full flow of materials to the batch and a homogenous mixture of the batch.

The working principle of the Ribbon Mixer

The ribbon mixer works on an established horizontal mixing principle whereby the outer ribbon circulates materials on the ends towards the center, whilst the inner ribbon circulates materials in the center towards the ends. This bi-directional movement forms both axial and radial flow, which leads to rapid and homogenous mixing. Being one of the longstanding Ribbon Blender Manufacturers, we suggest filling about 2/3 of the total capacity of the mixer to get the best blending capacity and the highest consistency.

Ribbon Mixer Construction and Design

We have ribbon mixers that have a precision and durability design. We are an established Industrial Blender Manufacturer, and we work with high-quality raw materials and improved fabrication methods to make our products have long service time and to operate hygienically.

Standard Construction Key Features

- U-shaped mixing trough to facilitate good movement of materials.

- Helical ribbon agitators are located inside and outside.

- Electric motor and heavy-duty gearbox.

- Shaft seals against leakage of material.

- Slide, pneumatic or manual gate discharge choice.

- Strong support system for vibration-free operation.

Key Benefits

- Homogeneous and uniform mixing will be attained.

- High efficiency short mixing cycles.

- Easy-clean and hygienic design.

- Low maintenance and energy-saving operation.

- Process-specific solutions that are custom-engineered.

- Fit to use in the production industry.

Material of Construction

Stainless Steel SS304

Stainless Steel SS316 / SS316L

Food-grade coated Mild steel (MS)

Technical Specifications

| Capacity of Batch | 50 liters to 10,000 liters |

| Mixing Time | 5-15 minutes (depending on material) |

| Drive System | Direct or chain-driven gearbox. |

| Motor Power | According to the size and use of batches. |

| Optional Features | Vacuum system, cooling jacket, heating jacket. |

Applications

Food Industry

Spices, flour mix, seasoning blends, premixes.

Pharmaceutical Industry

Excipients, dry powders, and herbal preparations.

Chemical Industry

Detergents, pigments, polymers, chemicals.

Cosmetic Industry

face packs, cosmetic bases, talcum powder.

Agriculture & Feed

Feed, fertilizer blends, premixes.

Manufacturer and Exporter of Ribbon Mixer You Can Trust

We are a reputable Ribbon Mixer Manufacturers and Exporter of an Industrial Blender that delivers high-performance ribbon mixers that are of international quality. Each machine is well tested prior to shipment to guarantee safety and performance as well as life. We are the preferred choice of industrial mixing solutions in the global market due to our quality, customization, and customer satisfaction.